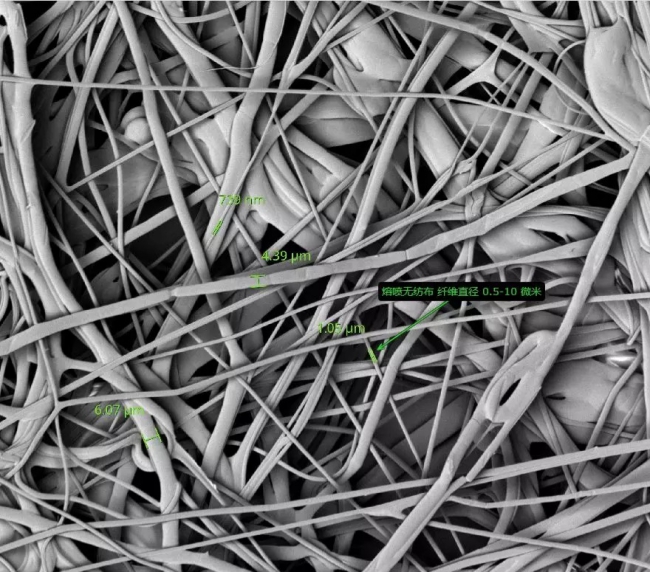

The melt-blown fabric is the filter layer in the middle of the mask, which can filter germs and prevent the spread of pathogenic bacteria. Melt spray is a kind of polypropylene polyacrylamide with a high melting index. It consists of many winding fibers stacked in any direction. The diameter of the fiber ranges from 0.5 to 10 m, and the diameter of the fiber is about one-thirtieth of a hair.

The picture below is a photo of the structure of the melt-blown cloth:

The gap between the melt-blown fabric is so large, how does it filter the virus infection in the natural environment? Although the specifications of the new dog parvovirus are not large, the virus infection cannot exist alone in the 100-nanometer technology (0.1μm). The key to its dissemination method is to divide the substance and the droplet infection when spraying the nose. Its size is around 5μm. It is one of them. Secondly, the melt-blown cloth is essentially a fiber filter, which keeps the filtration of droplets and other particles according to various filtration systems. According to the size of the droplet infectious particles and the cyclone rate, the fiber captures the virus-containing droplet infection according to a variety of systems:

Fiber filtration principle plan

1. Accumulation of inertial force: inertial impaction

When the particles are safely channeled according to the mesh structure bent by the filter material, the particles get rid of the cyclone and collide with the filter fiber due to inertia, and are intercepted by the attractive effect of the molecular structure. Large particles, high density, and faster interception are easy to use.

2. Intercepting accumulation: interception

The large particles that follow the cyclone fitness exercise are intercepted by the microporous filtering effect of the mechanical equipment that filters the raw materials. The ratio of particle diameter to filter paper fiber diameter compromises high blocking efficiency.

3. External diffusion accumulation: diffusion

The Brownian motion of the particles diffuses and shifts to the filter fiber, and is absorbed by the attractive effect of the molecular structure. It is easy to capture small particles, fine fibers, and low-speed fitness particles.

4. Electrostatic induction attracts accumulation: electrostatic attraction

Particles are accumulated by the electrostatic attraction of the filter fibers.

The longer the particles are, the stronger the accumulation effect of 1, 4, the larger the particles, the better the actual effect of 2, 3, so it is not that the smaller the particles, the more they cannot be filtered.

To have this filtering effect, the diameter of the fiber should be as small as possible, and the fiber diameter of the melt-blown cloth should be between 0.5-10μm, the bulk density is large, the sorting is high and the density is high, and the filtering characteristics are good. Melt blown cloth is used as the key filter layer in general medical equipment masks and N95 masks, which have excellent practical filtering effects on droplets or aerogels containing virus infections.

Although the raw materials of the S and M layers of the mask are all polypropylene special epoxy resin, there is a big difference in the production process and characteristics between the special melt-blown fabric and other non-cloth-free raw materials.

The above information is provided by a nonwoven felt supplier.